News & Events

News & Events

- Corrigendum-Upgradation of the Industrial Shed in NCB Campus, Ballabgarh, Haryana on EPC Mode

- Tender Notice-Upgradation of the Industrial Shed in NCB Campus, Ballabgarh, Haryana on EPC Mode

- NCB IC Event: Innovate Youth: Building Tomorrow's Entrepreneurs.

Consultancy services for getting NABL Accreditation as per ISO/IEC 17025:2017

Notice on Public Grievance

NCB – CCE EVENTS / Forthcoming Training Programmes

Proficiency Testing Schemes

NCCBM to host 17th International Congress on Chemistry of Cement (ICCC) in 2027 in New Delhi

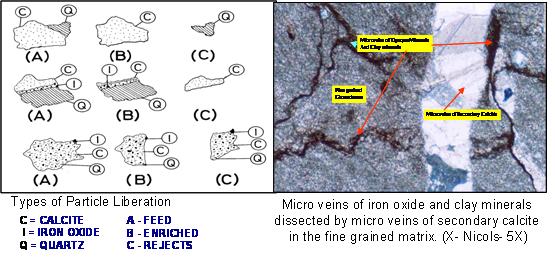

Beneficiation Studies of Low / Marginal Grade Limestone and Mine Rejects

Though India has huge reserves of limestone reserves, but the quality variation create hindrance in cement capacity development. The chemical composition, mineralogy and homogeneity depend upon the provenance and depositional environment of a limestone deposit. Silica (SiO2), Magnesia (MgO), Chloride (Cl), Iron (Fe2O3), Sulphide (SO3) are common deleterious constituents of limestone. The most common impurities associated with limestone deposits are clay and shale. Impurities may also be present as associated rock types like gneisses, schist, dolomite etc and in the form of intrusives also.

NCB has taken up the study for potential beneficiation of low/marginal grade limestone and mine rejects through physical separation techniques or dry beneficiation techniques such as size reduction and separation as most of the cement plants are based on dry process. The size reduction mainly involves the process of crushing and grinding known as comminution, the purpose is to liberate carbonates (calcite) from contaminated limestone. This is followed by size separation which can be accomplished by using classifiers, screens, cyclones etc. The product output has considerable difference in grain size and this result in to enrichment of calcite, silica and other chemical constituents separately.

The NCB’s investigation includes mineralogical characterization, mineral liberation studies, optical microscopy, their comminution sizing, sieving, and chemical analysis of various size fractions, physico-mechanical properties and X-Ray diffraction studies.